A fun, time-lapse video of Mountaintop in Motion.

All Posts

Tackling Indoor Air Pollution

Inside a mud hut, students seek a solution for developing countries.

The mud hut rises on the slope of a hill at the Mountaintop campus—a 6-by-8-foot replica of a cooking hut typically found in developing countries such as Uganda.

In searing heat, over the course of several June days, a group of students painstakingly built the hut. It is at the center of their search for ways to ventilate cooking huts naturally and to reduce the indoor air pollution that plagues much of the rural developing world.

Students use their feet to mix clay, sand, water and sawdust to make the mud adhesive for the hut. Photo courtesy of Breena Holland

The students toted tree limbs from a nearby wooded area to weave the hut’s frame and dug holes in the rocky soil to anchor the wood posts. Using their feet, they mixed clay, sand, water and sawdust in a kiddie pool to make mud adhesive for the walls. Then, by hand, they carefully built the 7-foot walls with the mud, slowly adding layers around the wood posts and tree limbs. On top they set a metal sheet roof.

“We are trying our best to make it as close to a cooking hut that would be created in developing nations, more specifically, in Uganda,” says graduate student and social scientist Marie Theresa Mejia, one of six students on the “Innovation in Ventilation” team. “We’re also finding ways to replicate it that would allow us to work in the time frame that we have.”

The combined engineering and social science research project, under way this summer at Mountaintop, not only explores practical solutions to indoor air pollution but also analyzes the underlying social issues that lead families to burn wood for fuel.

Numbers from the World Health Organization tell the story:

- Half of the world’s population, almost all in developing countries, burn biomass—wood, animal dung and crop residues—and coal to cook their food and heat their homes.

- Of those “forgotten” 3 billion people, more than 4 million die prematurely from illnesses linked to the pollutants emitted from the indoor burning of bio mass fuels.

- More than half of the premature deaths among children under age 5 stem from pneumonia caused by the soot that the children inhale indoors.

“When you breathe in black carbon, this tiny particulate matter, it causes respiratory disorders or it triggers respiratory problems, like asthma attacks,” says mentor Breena Holland, associate professor of political science and a participating faculty member in Lehigh’s Environmental Initiative. “There’s a lot of research linking exposure to fine particulate matter with pregnancy outcomes, cancer, heart disease, many significant health problems.”

Also mentoring the team is Kelly Austin, assistant professor of sociology and anthropology, a participating faculty member in the global studies program, and director of the health, medicine and society program.

Marie Theresa Mejia, Kellyn M. McCarthy, Yiliqi, and Amber Shrum slowly apply the mud to build the walls of the hut, a replica of a cooking hut found in Uganda. Photo courtesy of Breena Holland

With the hut now built outside of Building C at Mountaintop, the students will set up a cookstove inside, using a ring of rocks they unearthed while digging holes for posts.

Wearing face masks to protect them from breathing in harmful matter, they will start a wood fire and boil water. While starting and maintaining the fire to boil the water, they will use hand-held black carbon monitors to measure the level of the tiny, black particles being released into the air by the fire.

In addition to Mejia, the students involved in the project include Amber E. Schrum ’16, who is pursuing an integrated degree in engineering, arts and sciences (IDEAS); Dylan M. Friedgen-Veitch ‘16, environmental engineering; Shane McDevitt ’15, IDEAS; graduate student Yiliqi, environmental policy design; and graduate student Kellyn M. McCarthy, sociology.

The air quality monitoring will continue as the students naturally ventilate the hut in different ways, strategically placing holes in the mud walls for good air flow and perhaps cutting out a window. They’ll also try raising the height of the cookstove to determine if that would make a difference in protecting people from breathing in the particulate matter.

So far, global solutions have focused on replacing the traditional cookstoves in the rural developing world with cleaner, more efficient ones. Team member Schrum says, however, that new research suggests the “cleaner” cookstoves may not actually improve the air quality in the huts as initially believed.

Also, many families wind up selling their new cookstoves to get something they feel they need more, Holland said, or they do not easily adapt to the new technology.

“So poor people are still using the same technology they’ve always used, which is open fire burning in many cases.”

To keep with cultural norms and to provide low-cost solutions, the Mountaintop team is exploring whether an easily implemented natural ventilation system instead could reduce people’s exposure to black carbon in the huts and reduce the health risks of burning bio mass.

“Our intervention would not be providing them with something new in a way that their traditional values, their traditional way of doing things, are going to be completely taken out of the picture,” Mejia says. “Another thing to keep in mind is that many of the kitchens there have been built for years, so our intervention is something they can do without having to take their structures down and rebuild.”

The students may try cutting a window in the hut to determine whether it’s practical and whether it would make a difference in the inside air quality. In consultation with a contact in Uganda, Schrum said, they learned that cooking huts get built without windows because it’s cheaper and easier to not have to frame for a window. Plus, she said, windowless huts provide protection from torrential downpours and animals.

As part of the project, the students also are examining the social rights issues connected to the indoor air pollution problem.

“We dove into this project and we were able to look into whatever topic we wanted to look into,” Mejia says.

They are examining:

- The effect of gender roles on people’s health, given that women and children traditionally handle household chores.

- The effect of structural adjustment policies that emerged during the debt crisis in the mid-1980s as a way for poor countries to pay back lender countries. (What leads people to burn wood to cook in the first place?)

- The impact on neonatal and infant mortality.

“The issue of indoor air pollution is a multi-faceted issue,” Mejia says. “It’s not simply an issue you should care about because of the health issues but also because it’s connected to so many other things, such as economic status, general social status in terms of land property rights, female empowerment. It’s a public health issue but also a social rights issue.”

Story by Mary Ellen Alu

More photos by Christa Neu are available here.

Mountaintop in Motion – Many Feet Make Light Work

At Mountaintop, many feet make light work. Find out tomorrow, what Breena Holland, Mountaintop Mentor, and her Innovation in Ventilation team were doing getting muddy in this baby pool.

A Toy Story

Shannon Varcoe ’15 has created a wooden building-block toy that she hopes to market. “In an age of electronic toys, it brings it back to the basics. You really can’t be bad at this,” she says.

As a kid, Shannon Varcoe never read the manuals that came with her toys and games.

Simply put, she didn’t like following instructions.

So it’s fitting that Varcoe ’15 has created a wooden building-block toy that doesn’t come with a manual or instructions. “You let your creativity tell you what to do,” she says.

Funny thing, though: Varcoe didn’t set out to make a toy when she put together a wooden sculpture for a design class in her sophomore year. But the other students in her class started playing with the notched wooden pieces. And when she took some of the pieces home from college, a cousin who has Attention Deficit Disorder began playing with them too.

It got her thinking: “Could this be something?”

Today, Varcoe can be found at Mountaintop, in Launch Bay C, building on her idea. She is making more wooden prototypes, experimenting with different sizes, cuts and shapes. She is trying to figure out the number of pieces, and the lengths of those pieces, that should go into a wooden building-block set that she can sell.

She is also trying to come up with a name for her toy, a target market, and branding materials.

With hopes too of inspiring and helping those with ADD and Attention Deficient Hyperactivity Disorder (ADHD), she is studying how children with learning disabilities play and learn. She is designing her wooden blocks with those kids in mind.

“It’s very hands on,” says Varcoe, who is pursuing an Integrated Degree in Engineering, Arts and Sciences (IDEAS). “There’s really no wrong answer when you’re building with it. You can build whatever you want, with however many pieces you want.”

The toy’s pieces are made of unfinished, natural wood that vary in length, with angled cuts that allow for each piece to fit together. Though the toy is simple in design, she says, the structures that can be built are anything but simple. “It’s hard to build the same thing twice,” she says.

So far Varcoe has made more than 100 pieces with cuts of different angles. As she plays with the pieces, building around space, she has made both the abstract—which can hang as art work—as well as the practical, such as a laptop stand.

“In an age of electronic toys, it brings it back to the basics,” says Varcoe, describing her toy as she works with wooden pieces at her space in Launch Bay C. “You really can’t be bad at this.”

In the design class that got things rolling, Varcoe’s assignment was to create a sculpture inspired by three words pulled from a hat. She drew the words “small,” “minimal,” and “prop.” Varcoe had to work with paper, then poplar. She wound up cutting angled grooves in the wood as part of the function of her design.

When her cousin later played with the pieces, she says, “he was just combining them in all different ways and building different things.” He liked them so much that his mother eventually called her to ask for more pieces, which Varcoe gave as a Christmas gift. He also etched into them with wood-burning.

After the early interest, Varcoe began focusing on her project and taking the courses that could help her in her venture. Last year she won a first place in the Eureka! Social Ventures competition sponsored by the Baker Institute for Entrepreneurship, Creativity and Innovation. She also tested her toy at a Mini Maker Faire at Steel Stacks in Bethlehem, produced by the Baker Institute, where she found that children would instinctively pick up the pieces of her toy and play.

“I was really fascinated by the teamwork involved when kids played with it,” says Varcoe. “Kids who were strangers to each other were helping each other build things, or each kid was building something and figuring out ways to connect it. So that was really interesting.”

At the Mini Maker Faire, one child created a stool, then promptly sat on it. A mother and daughter competed to see who could build the tallest structure.

Varcoe took note of how many pieces the children used in their play—research into how many pieces, and what pieces, she should include in a set. She may do more research with children to try to come up with a name for the toy. “I haven’t found anything that fits what it is,” she says.

Through their play, kids can learn aspects of geometry, engineering and architecture. Varcoe says they can learn not only how to collaborate with design but also how to get something to be sturdy, stable and balanced. Kids might build something tall, then find that by turning their creation on its side they will make it look different.

Varcoe, who always wanted to be a toy inventor, has noticed that parents too have been eager to join in, perhaps out of nostalgia for the wooden toys they played with as kids. But, she says, they soon seem to realize that the toy is much different than something like Lincoln Logs and much more complex than they might have initially thought. She hopes she has created a toy that will be lasting.

Meanwhile, says Varcoe, “It’s been really fun and rewarding just to see people play with it and enjoy it.”

Photo by Christa Neu

Story by Mary Ellen Alu

Mountaintop in Motion – A Sea of Whiteboards

Mountaintop in Motion – Fish Arrive

The tilapia that are the stars of the Lehigh Aquaponics project have arrived.

Kimberly Hetrick ’14, one of the four students on the team, picked them up in Carlisle last week and delivered them to Mountaintop in a bright blue bucket.

The students aim to cultivate the fish while growing plants in water. You can read more about the project in a story at the Lehigh News Center.

The team also planted the seeds for the lettuce they hope to grow.

Photos by Stephanie Veto

Helping Kids with 3-D Printing

When Lehigh students Colleen Perry and Elena Ramirez saw an emotional video of a 2-year-old girl who could not move her arms until aided by a 3-D printed device, they knew their mission – to similarly use 3-D technology to help disabled children.

Putting out a call on Facebook for a mechanical engineer to help in their endeavor, they found fellow student Jeff Peisner ’15, who is joining them at Mountaintop this summer to create 3-D printed devices for use in pediatric rehabilitation.

“That’s where we think the technology is more needed,” said Ramirez ’15, in explaining why the group is focusing on children’s needs.

Enter Good Shepherd Rehabilitation Network, an Allentown-based facility that offers rehabilitative care to children—and adults—who have physical and cognitive disabilities, injuries and complex medical needs. The network has programs for those who suffered strokes, as well as for those who have had amputations or suffered sports, brain and spinal cord injuries.

Coincidentally, in the months before the students had pitched their project, John Grencer ’79, administrative manager, Technology Department, and strategic business planner at Good Shepherd, had turned to his alma mater, Lehigh University, for help in best utilizing 3-D technology in rehabilitative work.

Part of Grencer ’s job is to look at new technologies that Good Shepherd should consider adopting. The network, for example, is the largest clinical users of the Ekso Bionics exoskeleton, a robotic device that helps those with paralysis to stand and to walk.

Like the Lehigh students, Grencer got excited about the potential of 3-D printing after reading and learning about the technology. “That got me thinking,” said Grencer. Could Lehigh students demonstrate the potential of the technology to Good Shepherd’s doctors and therapists?

“3D printing has the potential to revolutionize the medical field,” said Perry ’15.

Lehigh professors and mentors linked the students and Good Shepherd. At first, Perry, Ramirez and Peisner wanted to 3-D print prosthetic hands for children, knowing they could easily design them on a computer, customize devices, and make them much more cheaply than high-tech designs.

But after talking with hand and occupational therapists at Good Shepherd, they quickly came to a realization: There’s less of a need for prosthetic hands and more of a need for exoskeletons, or devices that work around body parts, to help children who lose full or partial movements of their hands, possibly after suffering strokes.

“We wanted to expand our project to help more people,” said Perry, who, like Ramirez, is studying biomedical engineering.

Strokes in children are more common than people may think, Ramirez said. An estimated 6 in 100,000 children are affected nationwide, according to the National Stroke Association. Good Shepherd treats about 10 to 15 youngsters with strokes each year, both as inpatients and outpatients, Grencer said.

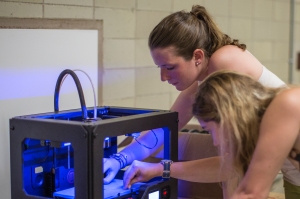

From left, Jeff Peisner, Elena Ramirez and Colleen Perry hope to create 3-D-printed exoskeletons that can one day be used in pediatric rehabilitation.

The students refocused their Mountaintop project and are now working on making prototypes for 3-D-printed exoskeletons that they hope can one day be customized for children and used in their rehabilitative therapy. They plan to share the results of their project with interested physicians and therapists at Good Shepherd in late July.

“An exoskeleton can go around the hand and facilitate some kind of movement in hopes of molding the brain to relearn the movements that the hand does,” Ramirez said.

Like prosthetics, exoskeletons can be highly complex and expensive, and they usually do not come in sizes small enough for children, the students said. Plus, for children who are still growing, inexpensive 3-D-printed devices make more sense. “It’s just not realistic for a child to be buying a new (high-tech) device that costs thousands of dollars every six months,” Ramirez said.

The students are creating their designs on laptops, then fabricating the specialized parts on a 3-D printer in a backroom at Building C at Mountaintop.

Peisner explained that they will experiment with rubber bands and strings in their creations to help translate children’s wrist movements into finger movements.

“We’re assuming our patients have wrist movement,” Peisner said. “While this might not affect all children with strokes because some might not have any wrist movement, it’s really all we can do right now to assure that (the device) stays mechanical.”

As they innovate and learn, they’re optimistic they can make a difference.

Photos by Christa Neu

Story by Mary Ellen Alu

Mountaintop in Motion – Hut in Progress

Mountaintop Mentor: Murray Itzkowitz

Murray Itzkowitz, department chair and professor of biological sciences, is an evolutionary biologist who studies the theoretical aspects of social behavior. His interest in the endangered Leon Springs Pupfish of West Texas was triggered when he inherited a ranch near Big Bend National Park along the border between Texas and Mexico.

For the past 15 years, Itzkowitz and his students have spent summers studying the mating habits of the pupfish in the 100-degree-plus West Texas heat. Alarmed by the decline in the pupfish’s population as well as its habitat, the group has applied for and received several grants from the Texas Fish and Wildlife Department. The group’s efforts are paying off, as the pupfish population has begun to rebound.

At Mountaintop this summer, Itzkowitz’s students are observing pupfish in wading pools whose temperature, salinity and light exposure replicate as nearly as possible the conditions that prevail in the cienegas, or rare and isolated desert marshlands where the Leon Springs pupfish lives. By controlling these and other critical variables, the group hopes to learn which environment best promotes the pupfish’s mating and, thus, its chances for survival.

Here, Itzkowitz shares his thoughts on Mountaintop and the opportunities it is providing his students.

What are your thoughts in general about Mountaintop? What is the value it holds for students at Lehigh?

I have always been amused that many people separate their time at a university from what comes after- “the real world.” I’m not sure what is meant by a “real” or “unreal” world, but I think the common knowledge is that the university curriculum is composed of material that is largely unimportant after graduation. It is not surprising that online courses are the current fad when so many believe that university courses are just a bunch of lectures and exams. To further diminish the university education, we often hear that successful people have talents that do not require a university education, e.g., intelligence, interest, and the ability to form creative collaborations. But are these successful people really unique? With the new space available at the Mountaintop, Lehigh is testing the idea that these skills can be learned, nurtured, developed and ready for use at the time of graduation. Judging from my group, I see students using their already well-developed academic skills to understand complex problems. I see them developing communication skills that allow unique ideas to be heard, vetted and tested. Perhaps because of their project “ownership,” I also find them to be enthusiastic and hard-working. If Lehigh can expand this experience, I think we will provide students with a unique and important educational opportunity. When students leave here, the “real world” they will soon experience will be pretty much what they experienced at Lehigh.

How did you get involved with this project and these students?

I got involved for two reasons: First, Lehigh provided me with an opportunity to expand my research on the conservation of a highly endangered desert species fish found in West Texas. Second, I was intrigued by an educational model in which the boundaries between faculty and students blur, by allowing students to become research collaborators while faculty serve more in the role of a mentor. I thought it was a worthwhile education experiment to see how or if creative collaborations among students could enhance or even replace the lecture-test paradigm.

What value does this space at Mountaintop hold for this project in particular?

The project itself could not have been done without the large amount of space available for the experiment. However, the space itself was unique because it was controlled by the students and thus allowed them to have far more creativity on the direction of the research. I also believe the close proximity of other undergraduate projects will fuel their enthusiasm, creativity and collaboration.

What challenges do you think your team will encounter during their project?

The road to a successful scientific outcome is littered with obstacles, and the ability of the team to navigate these obstacles is the challenge. The large amount of work required to do the experiments and the complexities of problems can only be overcome by the collaborating spirit of the team’s members.

What hopes do you have for your teams’ outcomes?

I have two straightforward hopes: First, I hope the project is successful and will provide a model for conserving a very unique group of desert spring fishes. Second, I hope these students enjoy and gain from this unique educational experience.

One Group’s Trash is Another’s Compost

The students arrive, as they do every morning, toting blue buckets filled with scraps of food from Lehigh’s Brodhead Student Restaurant.

Pitchforks in hand, they turn the compost pile at the edge of Lehigh’s Community Garden and add the new waste: fries, grilled cheese sandwiches, spaghetti and other leftovers as well as bits of food discarded while preparing meals.

A couple of rodents scurry out of the pungent pile, but the students are unfazed as they complete their work. They aerate the mound, take temperature readings and add wood chips to balance carbon and nitrogen ratios. On this day, with rain in the forecast, they’ll hold off on hosing things down so as to not make the pile too moist.

This is the GR2OW project, one of the multiple initiatives based at Mountaintop that are under way this summer. The group acronym, conceived by the four students on the team, stands for the Green Resource Recovery of Waste. And that’s just what the group aims to do–turn all of Lehigh’s food waste into compost that can be used to fertilize greenery and other plant beds on campus, and then grow food to serve in campus dining halls.

“It’s not that far out of reach, and it’s definitely not without precedent,” said Alec Entress’ 16, one of the students on the team.

But establishing a composting facility at Lehigh, and closing the food loop, is a long-term goal, one that the students know will require buy-in from other students, faculty and staff. The short-term goal is more easily attained—resuming composting on campus, at the Lehigh Community Garden on the Goodman campus, with the rich material being used to fertilize fruits and vegetables grown there.

The GR2OW team turns the compost pile at the Lehigh Community Garden on the Goodman campus. From left, Alec Entress, Tori Wiedorn, Ben Cicchillo and Aly Lang.

“By necessity, this has to continue,” said Entress, about efforts to design and implement an on-campus composting system for getting rid of Lehigh’s food waste.

Joining him in the endeavor are Aly Lang ’16, Tori Wiedorn ’17 and Ben Cicchillo ’17. All are pursuing an Integrated Degree in Engineering, Arts and Sciences (IDEAS).

Driven both by personal goals and environmental concerns, the students are building on previous student projects conducted by Environmental Science and IDEAS students. They are studying other composting systems, working closely with Facilities Services and trying to develop new technology to help with monitoring the health of their composting pile.

“Part of it is the wow factor,” said Entress. “We want to see what we can come up with, what we are capable of. So part of it is a personal test.”

But, adds Wiedorn, “It matters on a big picture level, because we’re not going to survive if we don’t change how we do things, if we don’t change how we do waste.”

Food waste has become a national concern. Americans threw out more than 36 million tons of food in 2012 alone, with only 5 percent diverted from landfills and incinerators for composting, according to the Environmental Protection Agency. Food will rot in landfills and become a source of methane, a potent greenhouse gas with more global warming potential than carbon dioxide, the EPA said.

That is not lost on the GR2OW group.

Wiedorn talks passionately about “how much better we could make Lehigh by doing something so simple as composting.”

Last semester Entress helped collect data on the amount of food thrown out at Rathbone, the university’s largest dining hall. On average, he said, it amounted to 200 pounds each day. It is believed to be higher in the fall as incoming freshman adjust to the all-you-can-eat buffets, he said.

As part of their work this summer in the Mountaintop initiative, the GR2OW group collects about 100 pounds of food scraps and leftovers each week from Brodhead Student Restaurant and Entress’ own kitchen, as well as coffee grounds from Saxbys Coffee in south Bethlehem. Then they haul it by the bucket in their cars to the compost pile at the Lehigh Community Garden.

The students take temperature readings by hand and visually check the moisture level of the compost pile. They are working on a prototype to remotely gauge what is happening, a sensor they call SUSAN. They also are examining the potential economic benefit of on-site composting to make it more of a sell.

Cicchillo said he’s come to realize there’s a lot he can do to help the environment. “I can be a lot more aware of what I’m throwing out, what I’m using,” he said.

The federal government last year launched the Food Waste Challenge, calling on businesses, communities and other government agencies to cut down on the amount of food going to landfills. Lehigh University, which has developed a sustainability plan, participates in that challenge, said Delicia Nahman, the university’s sustainability officer.

As part of Lehigh’s efforts, Dining Services donated 470 pounds of food last year in a collection drive, said Nahman. The university also has rid its dining halls of food trays so that students won’t pile up food that they likely won’t eat and will toss. Also, Rathbone’s food waste is treated to reduce volume, and it’s sent to an off-campus farm for composting. Last year 46 tons of food waste was composted.

Nahman, who meets regularly with the GR2OW team, said the university is serious about considering on-site composting as a piece of the puzzle. “She got us pretty psyched to be working on this project and is going to help us set up a meeting with some important people to slingshot our project into orbit,” Lang wrote on the group’s blog.

The students divvy up duties to take advantage of their skills. Wiedorn, who is pursuing environmental engineering, examines state regulations for permitting requirements. Lang and Cicchillo, who are studying computer engineering, are working on sensor prototypes. Entress is looking at the big picture.

The students, as a group, continually look at “the what, how and why” of any of their ideas. “Why are we doing this?” said Lang. “We still go back to that.”

“We want to do good things at Lehigh,” said Entress, summing up. “We want to leave it better than we found it.”

Photos by Christa Neu

Story by Mary Ellen Alu

Mountaintop in Motion – Board of Trustees Reception

Last week, the summer ’14 students and faculty mentors played host to Board of Trustee members during an evening reception, allowing trustees to learn more about the research projects already underway at #LUMountaintop.

Photo credit: John Kish Photography

Mountaintop Mentor: Bryan Berger

Brian Berger, assistant professor of chemical engineering at Lehigh, has made a big name for himself with research that sees him working “at the interface of biophysics and engineering.”

This summer, Berger is bringing his unique expertise to Mountaintop, where he is mentoring two groups of students. One of those groups is working on a project called “Integrating Molecular and Bioengineering Approaches to Address Challenges in Microbial Pathogenesis,” and will be co-mentored by Xuanhong Cheng from the department of materials science and engineering and Vassie Ware from the department of biological sciences. The other group will be tackling “Scalable and affordable nanoparticle synthesis for water purification in the developing world,” and will also draw on the expertise of Steve McIntosh and Mark Snyder from the department of chemical and biomolecular engineering.

With his groups just getting to work in early June, Berger checked in to share his thoughts on Mountaintop–and the opportunities the initiative provides not only for students, but faculty members as well.

How did you get involved with these particular student groups?

Vassie Ware and I had been discussing research for a while, and it kept coming back to projects we had going on separately in our labs, but both dealing with aspects of bacterial pathogenesis. We started kicking around ideas. Vassie was helping us with some biological techniques in engineering E. coli, and we helped her with electroporation of some bacterial samples. Eventually we converged on the idea of integrating our projects this summer around a common theme of looking at mycobacterium, which presents a whole series of unique challenges. For me, I have the chance to learn more about phage biology, which has a number of interesting aspects that could be relevant to treating multi-drug resistant infections- Vassie has been working on this for a long time. This summer is giving us both a chance to go after some ideas we had been discussing for awhile and were excited to pursue.

With Steve and Mark, we arrived at a similar kind of outcome. Steve and I had been working on using biological systems to synthesis nanostructured materials, with a focus on low-cost, high-yield methods to overcome current limitations of chemical synthesis as part of a NSF EFRI grant. One interesting application of this work is in photodegradation of organic pollutants from wastewater, where nanotechnology presents several potential solutions, though none are cost-effective for large-scale implementation. This is particularly important in communities where access to electricity or other resources may be limited; in other words, the solution needs to be both cost-effective and robust to a wide range of working environments. So we needed someone with expertise in materials synthesis (i.e., Mark), and the three of us decided to go for it.

What value does the physical space at Mountaintop do for this project in particular?

I think integrating students from chemical engineering, bioengineering, biochemistry and biological sciences is valuable for both of our teams. The kinds of problems we are trying to address are ones that are inherently multi-disciplinary, and they need both graduate and undergraduate students from the life sciences and engineering working together with faculty from both as well.

Educationally, I feel this experience is also very important, as inevitably many of these students may go on to careers in industries such as pharmaceuticals, biotechnology, alternative energy or advanced materials, where the teams they will be working in will be comprised of engineers, scientists and people with diverse backgrounds in general. Thus, working together in diverse teams with undergraduate students, graduate students and faculty across colleges is key to providing a cutting-edge education in engineering and science.

What challenges do you think your team will encounter during their project?

I think learning the experimental techniques will take time, but I also think the students are very motivated to learn and are working hard. Biological systems can also be unpredictable, particularly when we are trying to merge aspects of biology with engineered systems for a hybrid prototype, so we will likely encounter challenges this summer in producing the biological components necessary for our respective projects.

What hopes do you have for your teams’ outcomes?

I hope we can demonstrate feasibility for the concepts behind both projects. I think we can. I also hope several of these students will continue these projects as sponsored undergraduate research throughout the 2014-2015 academic year, so we can continue to build off of the success we have this summer.

Mountaintop Mentor: Kelly Austin

Lehigh prides itself on fostering a professor-as-mentor approach, and this summer at Mountaintop is just another example of that long-established ethos.

Throughout the summer, this blog will be bringing you interviews with the professors that are mentoring the student-driven projects at Mountaintop. First up in our series is Kelly Austin, assistant professor of sociology in the department of sociology and anthropology.

Austin, along with Associate Professor Breena Holland, is mentoring a group of six students working on the project called “Innovation in ventilation: A combined research experience on indoor air pollution.” Soon after the students got to work in late May, Austin spoke to us about her thoughts on the Mountaintop project and her hopes for her group this summer.

What, in your mind, is the value of the Mountaintop experience? What can it offer to students?

The Mountaintop program is really amazing, as it has allowed me to develop truly interdisciplinary research ideas and teams of students. Our team of students is comprised of three social scientists and three engineers. These students would never have come together (or seen the value of coming together) without the support from Mountaintop. Our project involves designing innovations in ventilation to reduce indoor air pollution in small kitchens in Sub-Saharan African nations, as well as producing scholarly research that examines the larger socio-economic causes of solid fuel use and the health risks associated with indoor air pollution.

It is amazing to see the entire team working together and learning with one another. They are learning that the best-designed intervention is useless if it is not culturally appropriate, or if it doesn’t take into account social inequalities in household decision-making where the intervention is targeted. Thus, engineers and social scientists really do need to come together to make projects like this successful. Daily, I get to witness “ah-ha” moments like when a sociology student learns about the relevance of wind currents for our project or when an engineering student learns about the role of gender inequality in vulnerabilities to indoor air pollution.

How did you get involved with this project and these students?

I got interested in this project after conducting my own fieldwork in rural Uganda related to HIV and malaria. I had heard of the problems with indoor air pollution before, but was very shocked to see women cooking in tiny huts for hours with no windows. As I started to delve into the issue further with one of my students, Theresa, who is currently on my Mountaintop project, we came to learn that key interventions around indoor air pollution involve implementing new stoves or fuel sources. However, this is really not a feasible intervention for very poor households who cannot afford to buy fuels or for which the stove design is not culturally appropriate. We instead thought that focusing on interventions to simply improve ventilation may be more appropriate to implement, and more likely to be adopted by the household, as it does not require purchasing a new fuel source, etc.

I have had the pleasure of working with four of the students on the project before, including all three social scientists and one of the engineers. Amber, one of the team’s engineers who was on another interdisciplinary team I facilitated, helped me to identify two more engineers who would be great to work on this project. So really, the team naturally came together given the students’ interests and different expertise on the issue, and was student-driven in its formation as well.

What value does the space and/or unique approach to learning offered at Mountaintop do for this project in particular?

I spoke to the value of an interdisciplinary approach in my response to question one, so I will focus on the space aspect here. The space at Mountaintop is truly necessary for our project. This week, the students will begin building a mock kitchen using sticks and clay–just as is it is done in Uganda. They have already begun harvesting poles and smaller sticks and storing them at our work space at Mountaintop. It would have been impossible to do a project like this without the raw and large space that Mountaintop provides. Without having the space to really be able to get their hands dirty (and the space dirty, too), we would not have been able to carry out such a project.

What hopes do you have for your team’s outcome?

Each of the social science students have the goal of producing a scholarly research article, and the team of engineers also plans to write a publishable paper framed as a service learning piece which details the results of our experiments comparing the success of the different ventilation interventions being tested. We also hope to apply for funding in the fall to support actually implementing the best identified intervention(s) at kitchens in Uganda. This would really bring the project full-circle, and could potentially have a global impact that improves quality of life for people in poor nations.

Opening Day for Mountaintop 2014

It’s official: the second summer of Mountaintop at Lehigh is under way.

On Tuesday, the first of the 20 student groups working on Mountaintop projects this year began moving into Building C. The excitement of the big day was captured by writer Mary Ellen Alu and photographer Christa Neu from Lehigh’s Office of University Communications and Public Affairs.

You can read read Mary Ellen’s story, and see some of Christa’s photographs, at the Lehigh News Center.

Also writing about opening day at Mountaintop were the students behind the GR2OW project, who are working to design and implement a responsible system for food waste disposal for Lehigh’s campus and the Bethlehem community. In a blog post that succinctly captured the spirit of the Mountaintop project, team member Aly Lang ’15 wrote:

Advisors are great guidelines, but that’s just it, they are guiding us and nothing more. We are coming up with the “assignment” on our own. It’s our project. It’s our baby, and there are no limitations to where it can go besides ourselves. We are our own limits. Which is sweet and scary at the same time.

Capturing Mountaintop in Transition, Through ‘Complexity’

The former Bethlehem Steel research facilities known as Buildings B and C are now open to Lehigh students working on twenty different projects through the innovative Mountaintop program.

But before the buildings were cleaned out and prepared for Mountaintop, photographer Theo Anderson explored the bays and their lingering connections to Bethlehem Steel through the exhibit “Complexity,” in which he captures the buildings as they were before renovation. Anderson views such physical places as opportunities for transformation.

As he notes: “My intent was not to document, but rather to explore visual structure and form, free from preconception.” His exhibit was featured on campus this spring.

Anderson’s photos explore the bays’ transitions from oxidized, crumbling work spaces to a home for higher level thinkers and innovators to collaborate together.

The images from ‘Complexity’ can be viewed here.